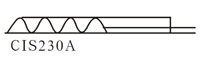

a)CIS230A CORRUGATED GASKET

These are sheet metal gaskets with concentric surface corrugations for better surface contact, in which the spring effect of the metal is also utilized for upgrading its sealing quality. A low seating stress equivalent to that for a corrugated asbestos joint sheet is sufficient. Furthermore, since the degree of heat-resistance is almost the same as that of the metal jacket, these are widely used in class 150 and 300 valve caps. b)CIS230B SERRATED GASKET

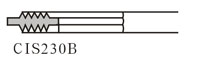

These gaskets are used for high temperature and high pressure steam, gas line valve caps and pipe flanges, they have sharp '60 or '90 concentric grooves machined at 1mm pitch over the plain metal surface. These sharp points take up the surface contact pressure very effective where a narrow flange width is required and can be usefully employed where heavy tightening is not possible because of the material quality and construction of the flange. c)CIS230C FLAT METAL GASKET

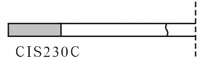

These are particularly economical gaskets of simple form stamped out from rolled metal sheet or machined out of flat form materials, and are used for high temperature and high pressure pipe flanges, valve caps and pressure vessel covers. d)CIS230D OCTAGON GASKET

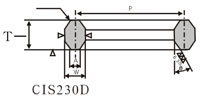

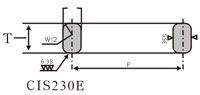

e)CIS230E ELLIPSE GASKET

|